It’s probably no secret that I’m an inconsiderate jerk…for that reason, I love mechanical keyboards and how incredibly loud they are! Kidding, kidding! …mostly. I love mechanical keyboards though, I used to use nothing but the holy grail of old-school keyboards; the IBM Model-M, a ‘buckling spring’ keyboard, and the original PS/2 keyboard…because, duh, it was the keyboard that came with the IBM PS/2. Loud as hell and built like a tank, made out of other smaller tanks, made from an alloy of adamantium and mithril. Anyway, when you spend over a decade on the computer 18 hours a day, typically on no less than half a dozen IRC channels at any given time, eventually you’re going to need an ergonomic keyboard or your hands are quite simply going to drop off at the wrists…

This meant giving up my glorious Model M…and for about another decade, I’ve been stuck using Microsoft Natural keyboards… Capacitive, rubber-dome based keyboards… They’re garbage, and they feel like garbage to type on. But what exactly is the alternative? Anyway, I go through a keyboard every 2-3 years because I simply start wearing out some keys– Oddly enough, the “U”, “F”, “K”, and “C”… (Kidding, kidding! …mostly.) –and it’s really annoying, and they’re expensive, and they still feel like complete garbage to type on.

Enter The ErgoDox

The original ErgoDox was a keyboard designed by Dominic “Dox” Beauchamp in October 2011, based on the key64 keyboard. (You can find the original GeekHack forum thread here.) Now, even though I’d seen it a couple times, it was just so bloody expensive that I wasn’t too excited…but I knew it was the kind of thing I desperately needed.

…5 years later…

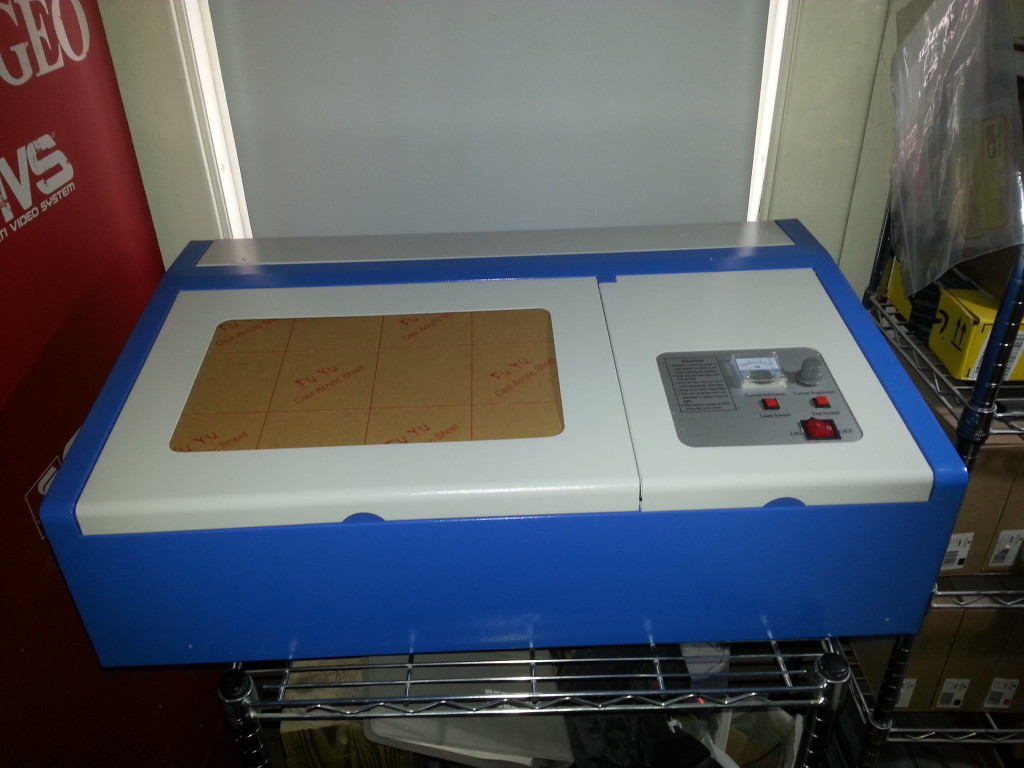

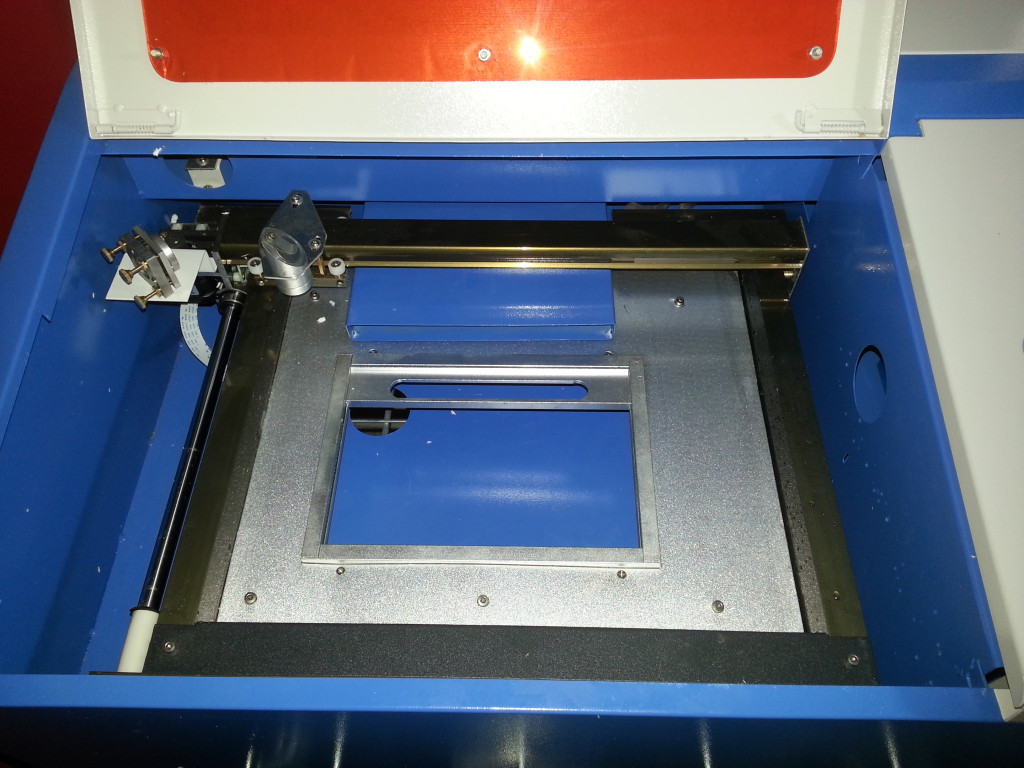

I’d been introduced to Massdrop a while back, and through their group buys, I managed to reacquire the greatest writing implement known to man, and level up one of my important Vault Dweller skills. So, when the opportunity presented itself around the end of January, I got on board the group buy for the Infinity ErgoDox by Input-Club. It makes a number of improvements over the original, including the addition of two RGB-backlit LCD screens, one on either half, which can display information such as which ‘layer’ the keyboard is currently in. See, the ErgoDox isn’t just fully customizable, but it’s got this crazy firmware setup where instead of just having an ‘Fn’ key layer like a laptop keyboard, you have the base layout and 7 additional layers that can be locked, shifted into, or locked for just the next key-press, etc. And it’s left/right side independent. So, even though it drastically reduces the number of keys versus a standard 104/105 key layout, you have limitless possibilities.

It was $199.99 with switches (plus another $39 for keycaps), I got it down to $155.99 for just the keyboard kit, because I was going to buy switches and keycaps separately…the latter would turn out to be a mistake however…

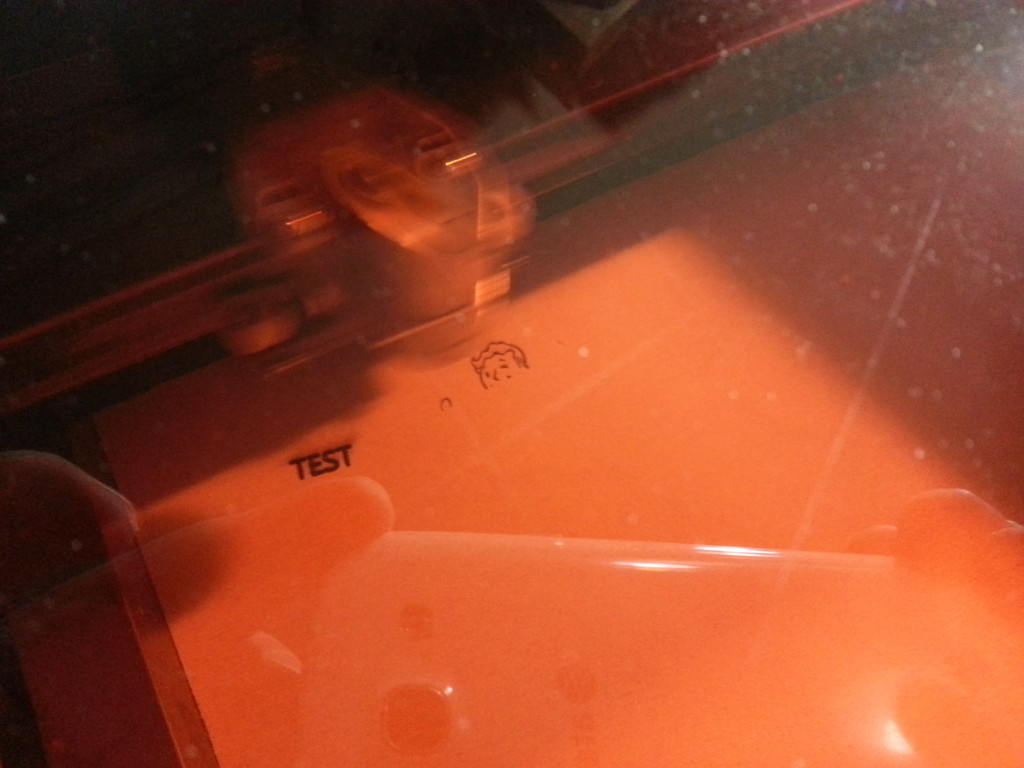

It’d be 4 months before the ErgoDox shipped, so I had time to source other items. A little while later, another group buy popped up, this one for Gateron Switches. (Clones of the standard Cherry MX mechanical switches that are held in such high regard by gamers and typists alike.) Of course, I didn’t really know what type of switches I wanted… Though I kind of figured I wanted ‘clicky’… That’s when I learned about ‘switch testers’, and oh hey, there was one on Massdrop! A switch tester is just a means of holding a bunch of different key switches so that you can test the feel. What was really cool about this one, was that for an additional $9 they were offering a PCB to turn it into a functional USB keypad. (Including keycaps, the PCB, and shipping, the total was $35.87) Now, obviously it wasn’t going to arrive in time for me to figure out which Gateron switches I wanted, so I bought a small one off Amazon with just Cherry MX switches and sort of guesstimated.

In the end, I went with Greens, because they’re clackers, and because they require the most force, and I’m a fairly heavy-handed typist.

So, in February, the switches arrived. In March, the switch tester arrived. And finally, just this last week, the Infinity ErgoDox arrived.

EDIT: This is interesting. So apparently, the switch tester was supposed to ship with the version 2.0 of the PCB, but they shipped the old one… So, at no additional cost, they sent us all a replacement, which turned out to be the brand new version 3.0, fresh off the production line.

Next Time: To Infinity ErgoDox, and Beyond!

Stay tuned for my next post on this subject where I’ll have a writeup on assembling my Infinity ErgoDox kit, the NKPC Switch Tester– including videos, I hope! –and probably some crazy mods to one or both of them. (Not to mention some other mechanical keyboard goodies!)

In the meantime, the like-minded clickity-clacky among you might be interested in the Mechanical Keyboards subreddit, or the Mechanical Keyboards community at Massdrop!