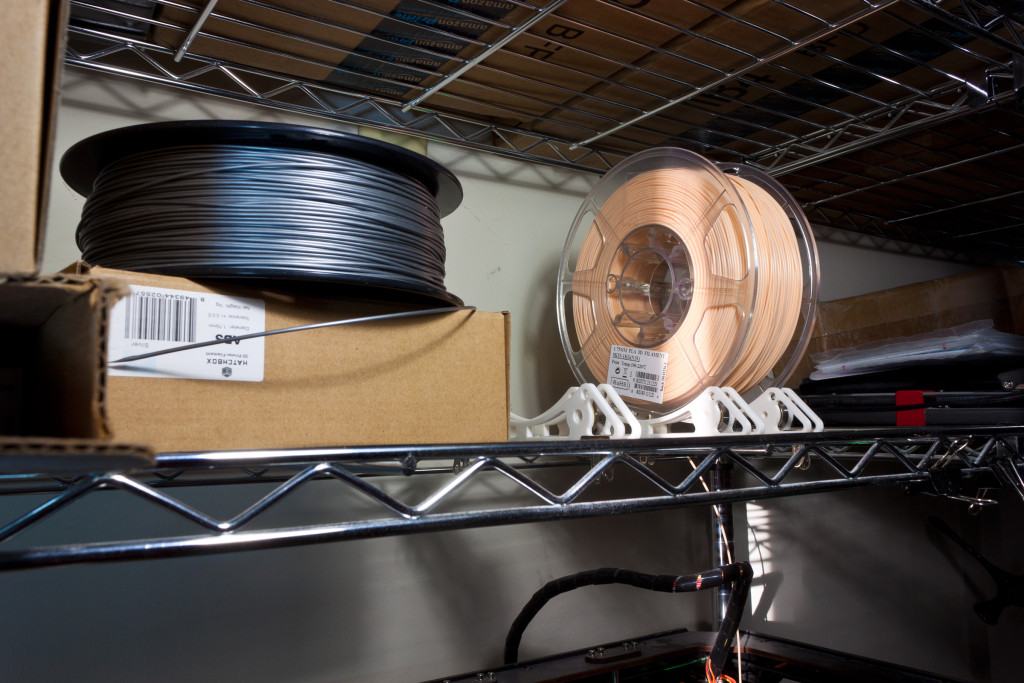

Week 37, 2015 – Everything’s (not) Ruined Forever!

So… That went well.

I ended up with a hard plug of PLA in the teflon tube of my printer’s hotend, and trying to clear it I mangled the teflon tube. Of course, to get even that far, I had to completely disassemble the hotend. And since I was doing that, I figured it was a good time to replace the thermocouple on the left extruder. And since I was doing that, I figured I’d do some upgrades I’d been planning on. And since I was doing that, I figured… Yeah, the slope just kept getting slipperier and slipperier.

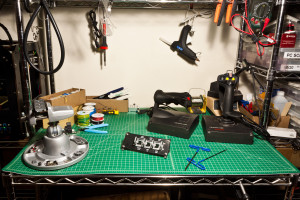

Things didn’t go terribly as you can can see in the few pictures I took… Nonetheless, things were not working correctly.

Dual-extruder assembly removed from printer.

Old thermocouple unplugged from MightyBoard.

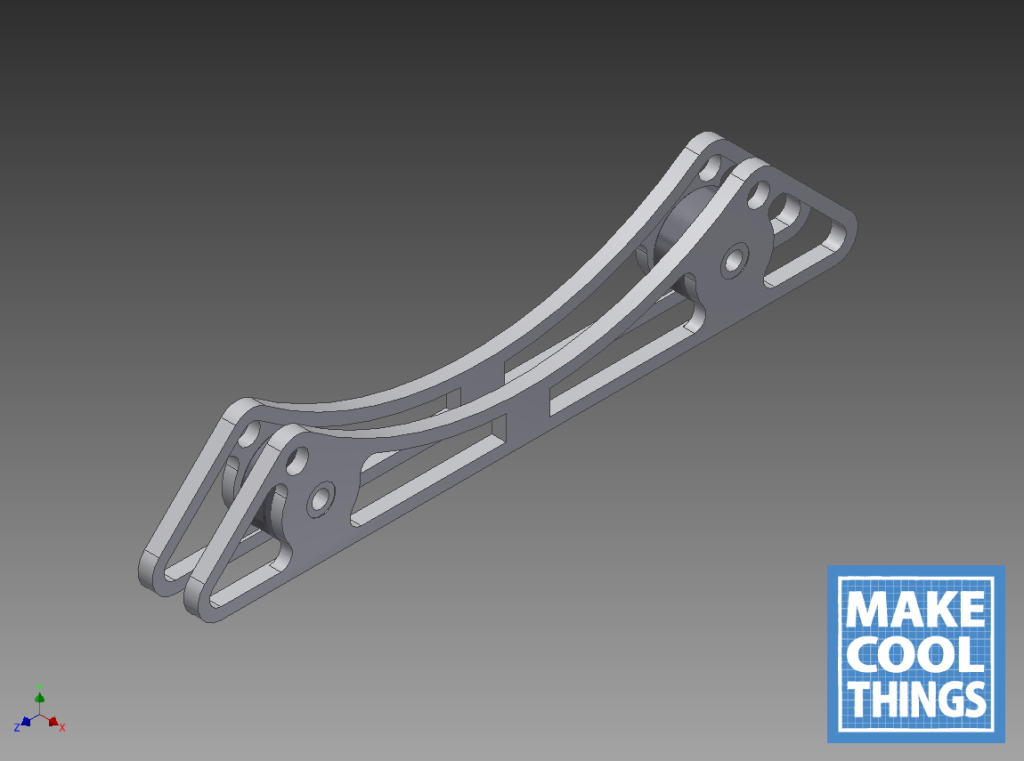

So, I got it back together, with some modifications… I like the replacement top plate… The 3D-printed strain relief for the cable bundle and the pneumatic press-fittings for the PTFE bowden tubing are fantastic additions. However, the spring I used in the new 3D-printed extruder was not up to the task and was simply not capable of extruding anything…

Partially re-assembled extruder.

I ended up disassembling and reassembling the whole thing two or three more times before I got it back up and running. Still, I’m not happy with the hotend barrels I got off Amazon, they have PTFE linings with a 2mm ID and 4mm OD, and are threaded full-length. The original barrels only had threads at the end, the rest was smooth, and used PTFE tubing with a 2mm ID but a 3mm OD, and the temperatures and behavior of the new parts were very different. Also, the original nozzles butted up against the barrel, but the PTFE tube extended down into the nozzle… The new barrels’ linings don’t stick out…but I do have additional nozzles designed to interface like that…so I put those on there. Nonetheless, I’m going to try and get some 3mm OD tubing.

UPDATE 2015-09-16: Teflon Tubing Trials and Tribulations.

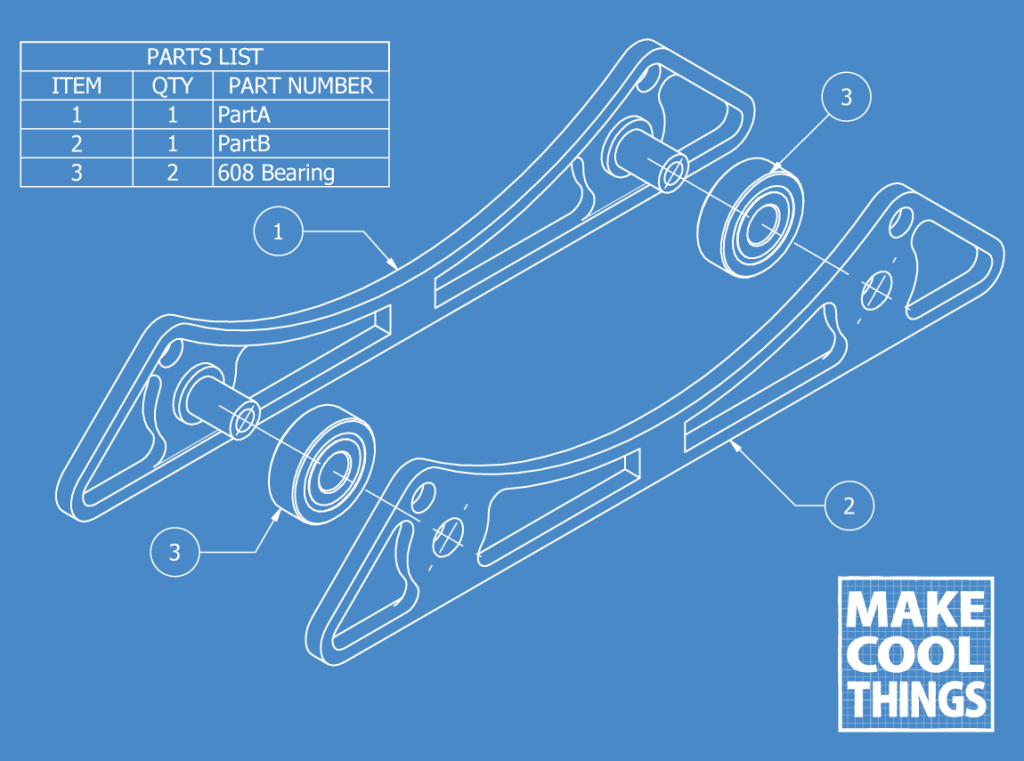

I couldn’t actually get PTFE tubing via Amazon Prime, so I had to order it from China– meaning it will be here whenever it bloody-well feels like it –and instead I ordered some PFA tubing that was rated for the same temps as PTFE. Anyway, that’s a god damned lie, because when I went to print PETG, the god damned PFA tube liquified. Not ‘melted’, not ‘distorted’ or ‘deformed’…it straight-up fucking liquified, leaving a quarter-inch blockage of rock-hard PFA in the end of the barrel. Managed to get printer back up and running by using one of the new nozzles, and the old barrel, and cutting the original PTFE liner so that it’d fit. (And thus removing the part that’d been all crinkled up.)

Melted PFA tubing.