Subscription-Based Licensing; You’re Doing it WRONG, Autodesk!

Well, here it is, exactly one week before my birthday, and looking at Autodesk’s site this morning, I stumbled across a wonderful little present they’ve decided to give me; as of the 31st, they will no longer offer the perpetual licenses that I have been hoping to one day be able to afford, opting instead for an equally unaffordable subscription plan. Fuck me, right?!

As far as I can tell, they won’t even be offering suites anymore. (See update at bottom!) You used to be able to get a whole suite of apps, such as 3D Studio Max, Inventor, AutoCAD and a ton of others, together for, what? Nine grand, one time? Now, you’ve got to pay like $1,900 a year just for Inventor. Which is fine for all their big corporate customers who make all their software purchases without a second thought anyway, but any individual who isn’t a student is basically fucked. Leaving people like me with no choice but to continue ‘stealing’ their software.

Yeah, I know, “What could some unwashed underachieving poor like you possibly know about such things?” Well, for starters, I can do the maths*, so that makes exactly one of us, Autodesk. I also know that when Adobe launched Creative Cloud in May 2012, and went Subscription-only a year later, they didn’t try to put the screws to their customers and make it too expensive for individuals and micro-businesses. An individual can get the whole fucking Creative Cloud suite– which actually has more apps than the old Creative Suite ever did –for $49.99 a month. That’s affordable. So affordable that it’s actually less trouble to go legit than to keep pirating it. Think about that. Adobe made the Creative Cloud so inexpensive that it’s literally not worth the hassle to steal it.

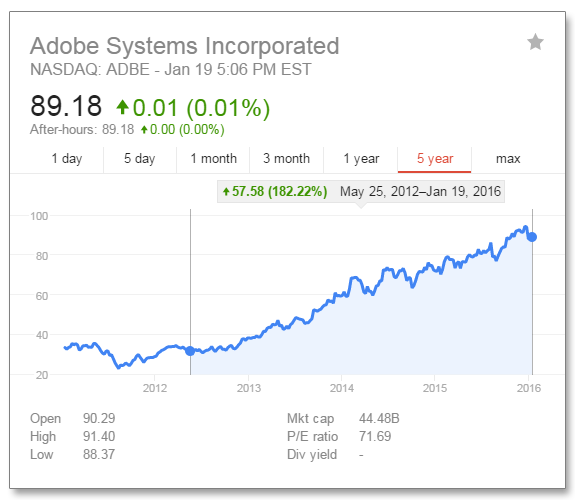

And you tell me, even with such low prices…how’s Adobe doing?

Spoiler Alert: Their stock price has almost TRIPLED since they began offering Creative Cloud,

a subscription plan so cheap that even poor-ass people like me can afford it.

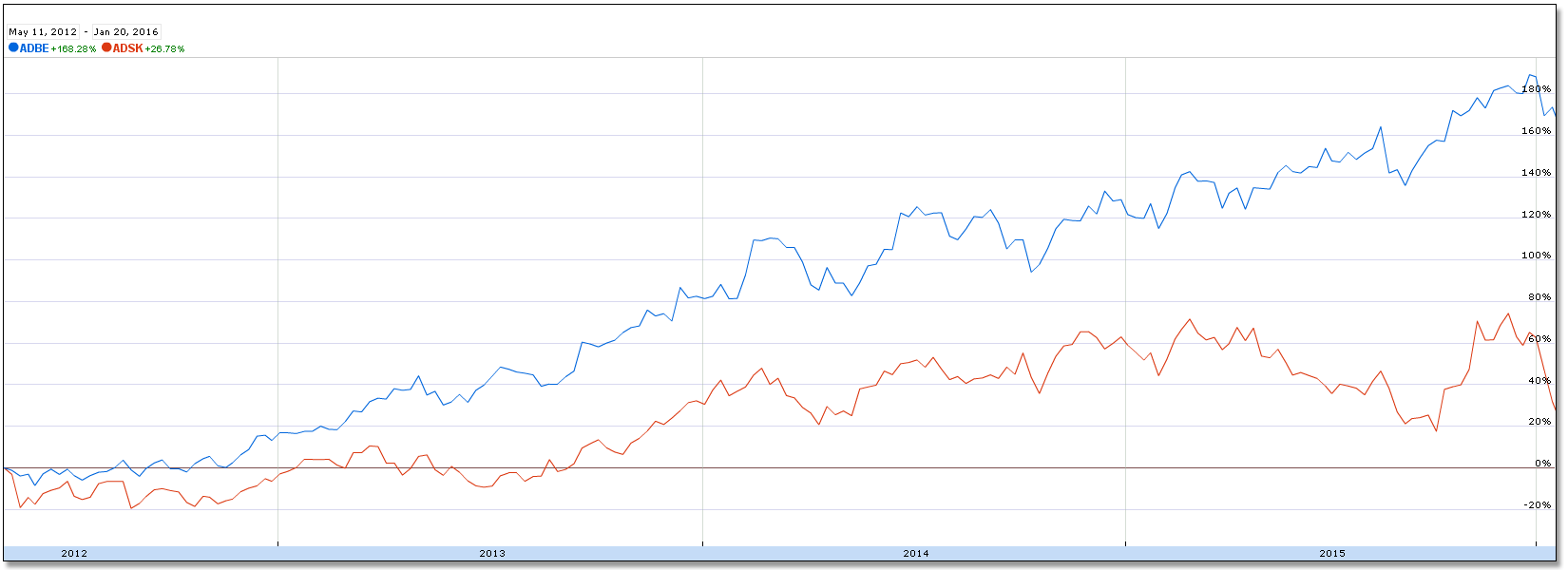

And because some people just have to be taught visually…

additional art courtesy of Google Finance:

(Click to embiggen.)

* Oh, right, ‘the maths’… I almost forgot. How many people out there do you suppose pirate your software, Autodesk? What if you made the subscription price more reasonable and even just ten percent of those people started paying for it? Well, you know what they’re paying you now? In the immortal words of the hero of Canton:

“Ten percent of nothin’ is, let me do the math here…

nothin’ and a nothin’, carry the nothin’…”